In the dynamic world of modern printing, where quality, speed, and versatility are key, the flexographic printing machine has emerged as a game-changer. This remarkable technology has revolutionized the printing industry by offering a unique combination of flexibility, cost-effectiveness, and environmental sustainability. Let’s delve into what makes the flexographic printing machine a driving force in today’s printing landscape.

A Versatile Workhorse

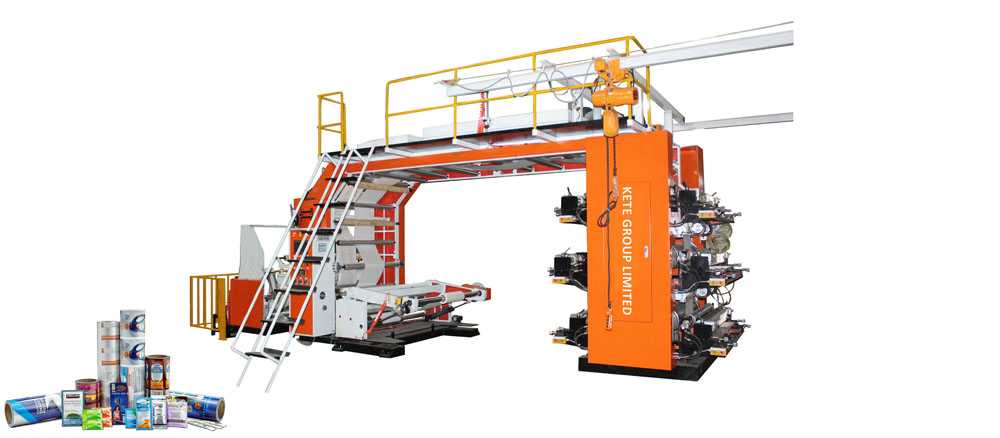

Flexography, commonly known as flexo printing, is a versatile printing process that uses flexible relief plates to print on various substrates, including paper, cardboard, plastic, and even metallic films. The beauty of flexography lies in its adaptability. It can be used to produce a wide range of products, from labels, packaging materials, and newspapers to wallpaper, corrugated boxes, and more. One of the standout features of flexo printing is its ability to work with a variety of inks, making it suitable for both water-based and solvent-based inks. This flexibility allows for vivid and high-quality printing on diverse materials, making it a preferred choice for numerous industries.

Speed and Efficiency

The rotogravure printing machine is known for its remarkable speed and efficiency. With advancements in technology, modern flexo machines can produce thousands of meters of printed material per minute. This speed makes it ideal for high-volume printing jobs, such as newspapers, packaging, and labels. It ensures that production targets are met without compromising quality. In addition to its speed, the flexographic printing machine is designed to be highly efficient. Its ability to print on a variety of materials reduces the need for multiple machines, streamlining the production process and cutting down on operational costs.

Cost-Effective Solution

Flexographic printing is a cost-effective solution for businesses of all sizes. The initial setup costs are relatively lower when compared to other printing methods, and its versatility means that businesses can use it for various printing needs. The affordability of flexographic printing makes it accessible to small businesses and startups, allowing them to compete on a larger scale without breaking the bank. Furthermore, the longevity of flexographic printing plates contributes to its cost-effectiveness. These plates can be used for thousands, if not millions, of impressions, which significantly reduces the recurring costs associated with plate replacements.

Flexographic printing is a cost-effective solution for businesses of all sizes. The initial setup costs are relatively lower when compared to other printing methods, and its versatility means that businesses can use it for various printing needs. The affordability of flexographic printing makes it accessible to small businesses and startups, allowing them to compete on a larger scale without breaking the bank. Furthermore, the longevity of flexographic printing plates contributes to its cost-effectiveness. These plates can be used for thousands, if not millions, of impressions, which significantly reduces the recurring costs associated with plate replacements.

Sustainability and Environmental Friendliness

In an era when environmental concerns are at the forefront, the flexographic printing machine stands out as an eco-friendly option. It offers various environmentally responsible advantages, starting with the ability to use water-based inks, which are less harmful to the environment than solvent-based inks. This is a crucial aspect for businesses looking to reduce their carbon footprint and adhere to environmental regulations. Additionally, flexographic printing reduces waste by utilizing minimal setup material and producing little to no hazardous byproducts. Its efficiency also contributes to sustainability, as it consumes fewer resources and energy compared to other printing methods.

The Future of Printing

The flexo printing machine is not only a current revolutionary force but also a technology with a bright future. Ongoing research and development are continuously enhancing its capabilities, making it even more adaptable, efficient, and environmentally friendly. This combination allows for more customization and personalization in printed materials, such as packaging, labels, and promotional items, which can be a game-changer in marketing and branding efforts.